paperboard packaging

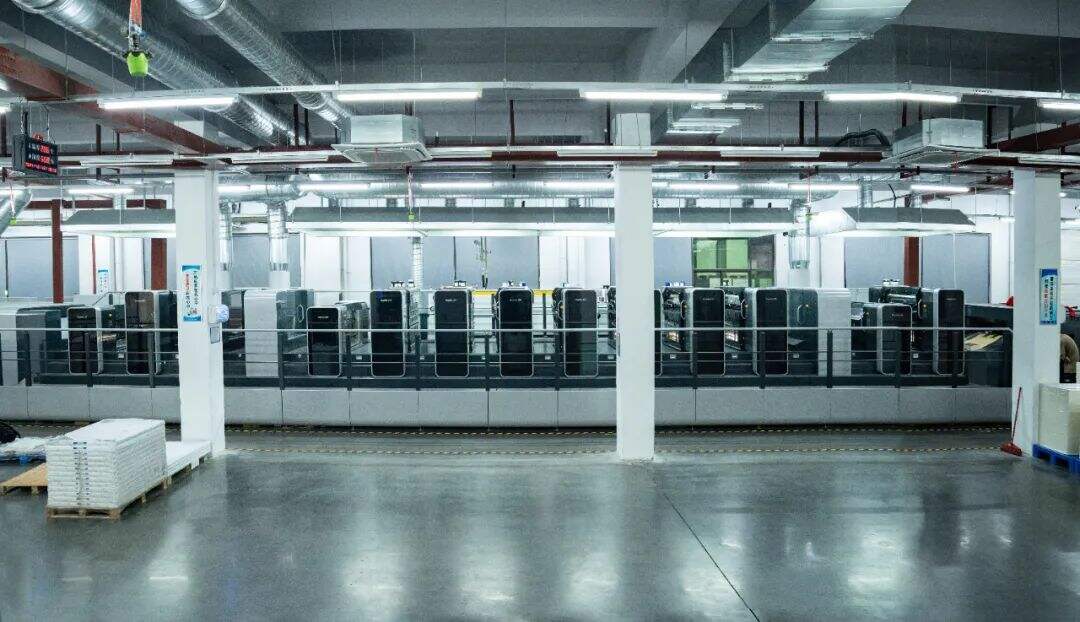

Paperboard packaging represents a versatile and sustainable solution that serves as the backbone of modern product protection and presentation across countless industries. This innovative material combines multiple layers of recycled and virgin fiber to create sturdy, lightweight containers that excel in both functionality and environmental responsibility. The core structure of paperboard packaging utilizes advanced manufacturing techniques that bond cellulose fibers into dense, uniform sheets capable of withstanding significant pressure while maintaining flexibility for complex folding patterns. Manufacturing processes incorporate precise moisture control, calendering operations, and specialized coating applications that enhance barrier properties against moisture, grease, and other environmental factors. The technological foundation includes various grades tailored to specific applications, from food-grade materials meeting stringent safety standards to industrial-strength variants designed for heavy-duty shipping requirements. Surface treatments such as clay coating, polyethylene lamination, or water-based barriers provide additional protection while preserving the material's inherent recyclability. Paperboard packaging demonstrates exceptional printability, accepting high-quality graphics through offset lithography, flexographic printing, and digital technologies that ensure vibrant colors and sharp text reproduction. The material's dimensional stability allows precise die-cutting operations that create intricate shapes, windows, and structural features without compromising integrity. Applications span retail boxes, food containers, pharmaceutical packaging, cosmetic cases, e-commerce shipping solutions, and point-of-purchase displays. Each application benefits from paperboard packaging's ability to provide structural protection while communicating brand messages through superior graphic reproduction. The manufacturing process incorporates quality control measures that ensure consistent thickness, density, and performance characteristics across production runs, enabling reliable automated packaging operations in high-speed production environments.