الطباعة بالأوفست لمصنع التغليف

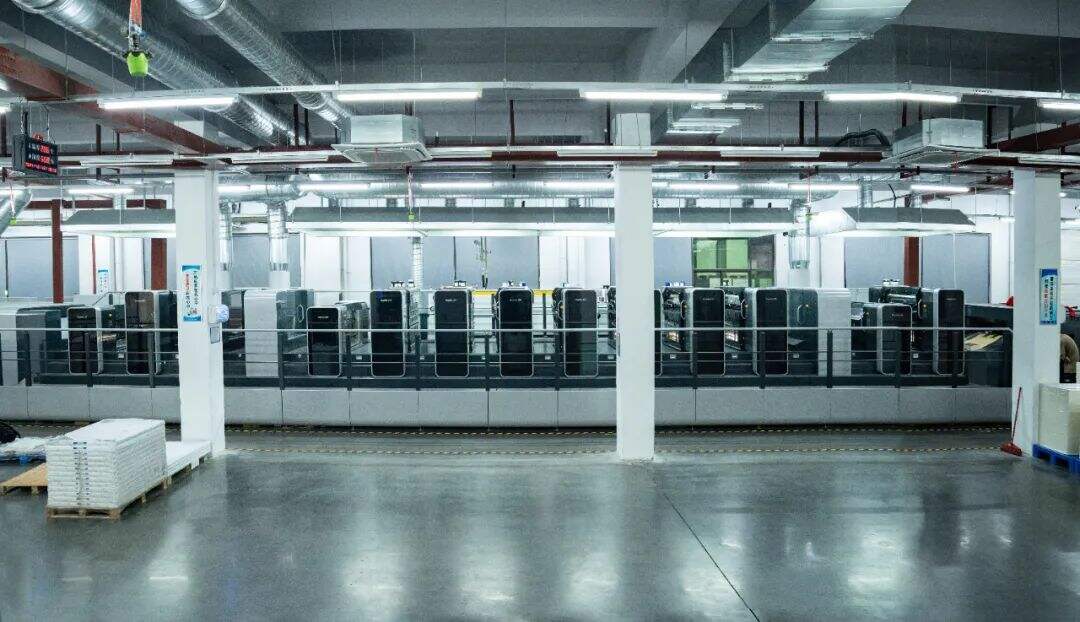

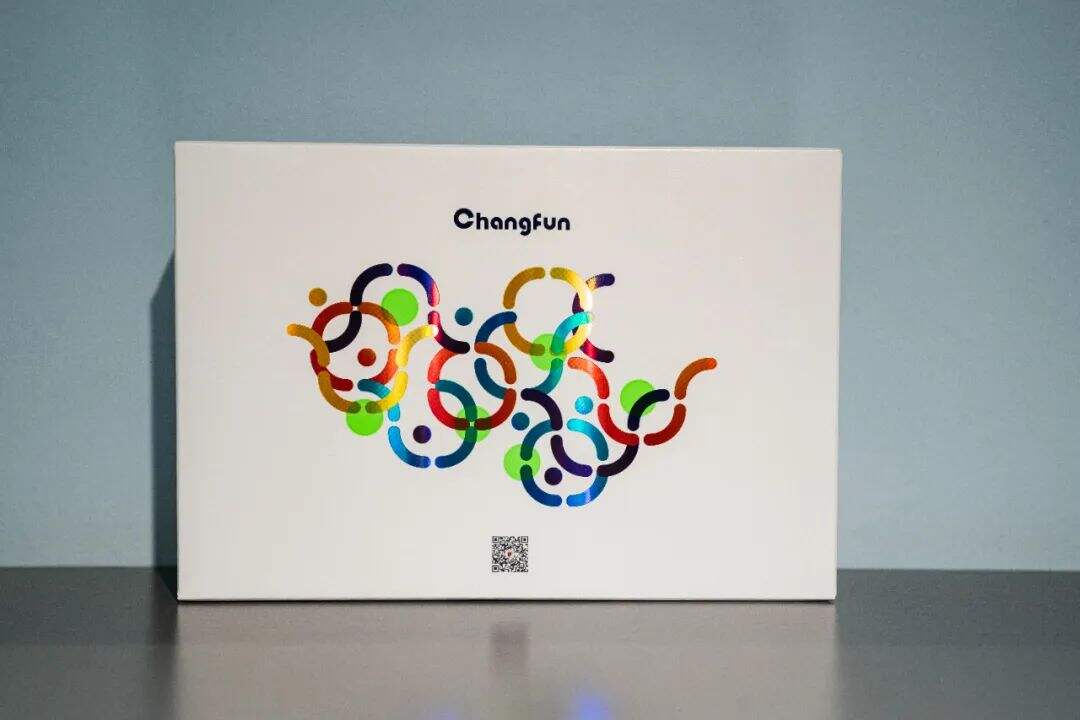

يمثل الطباعة الأوفستية لمصنع التغليف تقنية طباعية متطورة ثورة في صناعة التعبئة والتغليف بفضل جودتها العالية وكفاءتها الاستثنائية. تستخدم هذه الطريقة المتطورة أسطوانة مطاطية لنقل الحبر من ألواح الطباعة إلى مختلف مواد التغليف، مما يُنتج رسومًا ملونة ودقيقة تلبي المعايير الصارمة لأنظمة تغليف المستهلك الحديثة. يتضمن عملية الطباعة الأوفستية لمصنع التغليف مراحل متعددة، تبدأ بإعداد الملفات الرقمية حيث يتم تحويل التصاميم إلى ألواح طباعة باستخدام تقنية الحاسوب إلى اللوحة (Computer-to-Plate). ثم تُثبت هذه الألواح على أسطوانات داخل آلة الطباعة، حيث تتفاعل مع أنظمة الترطيب والحبر لإنتاج طبعات متسقة وعالية الجودة. تمتد الوظائف الرئيسية للطباعة الأوفستية لمصنع التغليف لما هو أبعد من إعادة إنتاج الصور البسيطة لتتضمن إدارة الألوان، والتوافق مع المواد الأساسية، والقدرة على التوسع في الإنتاج. تدمج أنظمة الطباعة الأوفستية الحديثة لمصانع التغليف تقنيات متقدمة لمطابقة الألوان تضمن اتساق الهوية التجارية عبر دفعات الإنتاج المختلفة والمواد المختلفة. تشمل السمات التقنية للطباعة الأوفستية لمصنع التغليف أنظمة تسجيل دقيقة تحافظ على المحاذاة المثالية بين الألوان المتعددة، وآليات تغيير الألواح تلقائيًا التي تقلل من أوقات الإعداد، وأنظمة توزيع حبر متطورة تضمن تغطية موحدة. يمكن لهذه الأنظمة التعامل مع مجموعة متنوعة من مواد التغليف بما في ذلك الورق المقوى، والمواد المموجة، والأفلام المرنة، والأوراق الخاصة ذات سماكات تتراوح من المناديل الخفيفة إلى الورق السميك المستخدم في صناديق التخزين الثقيلة. تمتد تطبيقات الطباعة الأوفستية لمصنع التغليف عبر قطاعات عديدة تشمل تغليف الأغذية والمشروبات، والحاويات الدوائية، وعلب مستحضرات التجميل، وتغليف الإلكترونيات، ومواد العرض بالتجزئة. تتفوق هذه الطريقة في إنتاج تصاميم معقدة تتضمن تفاصيل دقيقة، وتدرجات لونية ناعمة، وصورًا عالية الجودة تعزز من جاذبية المنتج والتعرف على العلامة التجارية. تراقب أنظمة ضبط الجودة المدمجة في عمليات الطباعة الأوفستية لمصنع التغليف اتساق الألوان، ودقة المحاذاة، وكثافة الطباعة طوال فترة التشغيل، مما يضمن أن كل عبوة تفي بمعايير الجودة المحددة.