kartonова упаковка

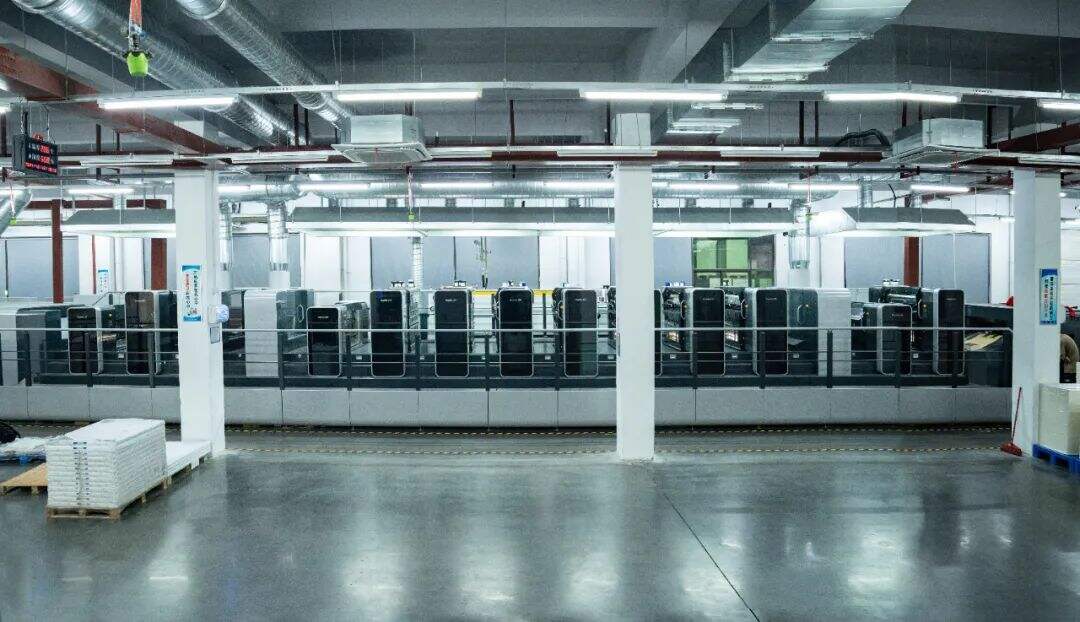

Картонената опаковка представлява универсално и устойчиво решение, което служи като основа за съвременната защита и представяне на продукти в безброй индустрии. Този иновативен материал комбинира няколко слоя от рециклирана и първична целулоза, за да се получат здрави, леки контейнери, които се отличават както по функционалност, така и по екологична отговорност. Основната структура на картонената опаковка използва напреднали производствени технологии, при които целулозните влакна се свързват в плътни, равномерни листове, способни да издържат значително налягане, като същевременно запазват гъвкавостта за сложни схеми на прегъване. Производствените процеси включват прецизен контрол на влажността, калибриране и специализирани покрития, които подобряват бариерните свойства срещу влага, мазнини и други външни фактори. Технологичната основа включва различни класове, адаптирани към конкретни приложения – от материали за хранителни продукти, отговарящи на строги стандарти за безопасност, до индустриални варианти с повишена якост, предназначени за тежки транспортни нужди. Повърхностни обработки като глинено покритие, ламиниране с полиетилен или водно разтворими бариери осигуряват допълнителна защита, като запазват вродената преработимост на материала. Картонената опаковка притежава изключителна печатаемост и позволява висококачествена графика чрез офсетна литография, флексографско печатане и цифрови технологии, които гарантират ярки цветове и прецизна възпроизведба на текст. Размерната стабилност на материала позволява прецизни операции по изрязване с дай, чрез които се създават сложни форми, прозорчета и структурни елементи, без да се компрометира цялостността. Приложенията обхващат търговски кутии, хранителни контейнери, фармацевтични опаковки, козметични кутии, решения за доставка в електронната търговия и дисплеи за точките на продажба. Всяко приложение извлича полза от способността на картонената опаковка да осигурява структурна защита, като едновременно предава послания на бранда чрез висококачествена графична възпроизведба. Производственият процес включва мерки за контрол на качеството, които гарантират последователна дебелина, плътност и експлоатационни характеристики в рамките на серийното производство, осигурявайки надеждни автоматизирани опаковъчни операции в среди с висока скорост на производство.