Offset printing is one of the most widely used printing techniques across various industries due to its high-quality output and cost efficiency on large print runs. It involves transferring an inked image from a plate to a rubber blanket, then onto the printing surface. This indirect printing process produces sharp and consistent images, making it ideal for a broad range of packaging and promotional products. In this article, we explore what types of products are best suited for offset printing, highlighting the advantages and practical applications of this versatile printing method.

Offset printing offers exceptional image sharpness and color consistency, which is why it’s preferred for products requiring high-resolution graphics. The process supports a wide color gamut and precise color matching, essential for brand identity and marketing materials. This makes offset printing a prime choice when visual appeal is critical.

While initial setup costs can be higher compared to digital printing, offset printing becomes more economical as the quantity increases. For medium to large print volumes, the per-unit cost is significantly reduced, making it a financially sensible option for mass production.

Offset printing is adaptable to many substrates including paper, cardboard, plastic films, and even metal foils. This flexibility allows manufacturers to use offset printing across various product types, from packaging to stationery and promotional materials.

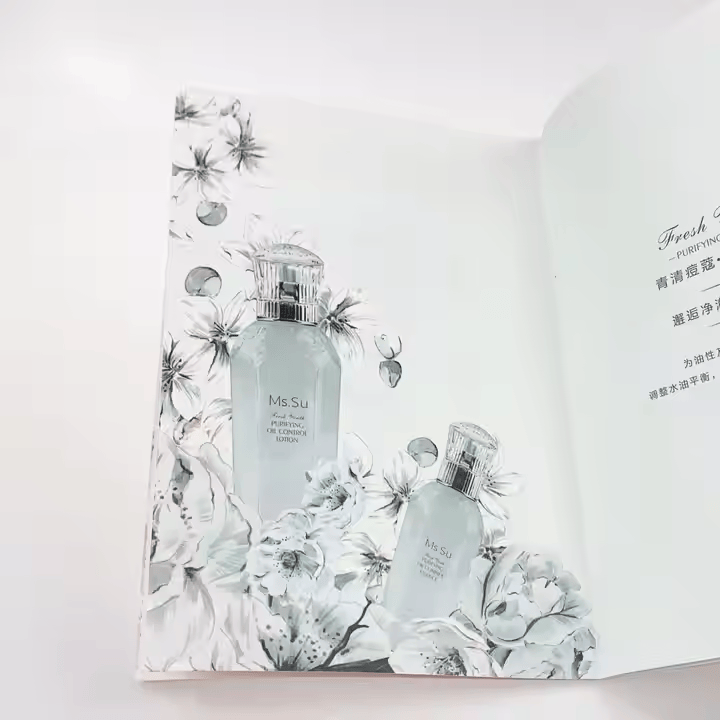

Offset printing excels in producing packaging materials that require detailed graphics and consistent color reproduction. Products such as folding cartons, paperboard boxes, and labels for cosmetics, food, and pharmaceuticals often utilize offset printing to achieve attractive and durable finishes. Its ability to print on coated and uncoated paperboards enhances the packaging’s visual and tactile qualities.

The print quality and color accuracy provided by offset printing make it ideal for magazines, catalogs, and books. The technique supports high-speed production of large volumes, while ensuring consistent image quality throughout the print run. Additionally, offset printing accommodates various paper types and finishes, from glossy to matte.

Brochures, flyers, posters, and other marketing collateral benefit from offset printing’s precision and vibrancy. These materials often demand eye-catching visuals and accurate color reproduction to engage consumers, making offset printing an excellent choice for promotional print products.

Offset printing produces professional and elegant stationery items, including letterheads, envelopes, and business cards. The process supports special finishing techniques such as embossing, foil stamping, and spot UV coating, enhancing the tactile and visual appeal of corporate materials.

Offset printing is most cost-effective for large print runs. Small quantities may be more economically printed using digital methods due to the initial setup costs involved with plate making. Businesses should evaluate their volume requirements to determine if offset printing is the right fit.

Products requiring high-detail images, fine lines, and smooth gradients benefit greatly from offset printing. The technology handles complex designs efficiently, maintaining sharpness and color depth that can surpass other printing techniques.

While offset printing is compatible with many substrates, not all materials are suitable for the inks and processes used. Coated papers and boards are often preferred to achieve the best image quality, but offset can be adapted to specialty materials depending on the application.

In packaging, consistent brand presentation is critical. Offset printing delivers uniform colors and sharp images across thousands of units, ensuring each package reflects the brand’s standards.

Offset inks offer good resistance to wear, making packaging more durable during handling and shipping. Moreover, offset printing supports a range of finishing options like varnishes and lamination, which protect the print and enhance aesthetics.

As packaging demands grow, offset printing scales efficiently. Its ability to handle large orders without compromising quality is a major advantage for manufacturers aiming to balance production speed and cost.

Hybrid printing solutions combine offset and digital printing to leverage the strengths of both. This allows short runs or variable data printing alongside high-quality large runs, offering flexibility for customized packaging and limited editions.

Sustainability is influencing offset printing, with increased use of vegetable-based inks and recyclable substrates. These developments help reduce the environmental impact of printed products while maintaining print quality.

Improved color profiling and calibration tools enable more accurate and consistent color reproduction, supporting brand fidelity across multiple print runs and materials.

Generally, offset printing is more cost-effective for medium to large print runs due to setup costs. For very short runs, digital printing may be preferable.

Yes, offset printing can be adapted for certain plastic films and coated substrates, but ink adhesion and curing need to be carefully managed.

Offset printing offers superior color accuracy and is more economical at high volumes, while digital printing excels in speed and flexibility for short runs and customization.

Finishes include varnishing, lamination, embossing, foil stamping, and spot UV coating, all of which enhance durability and visual appeal.