چگونه جعبههای گل احساس لوکس بودن بستهبندی آرایشی را افزایش میدهد؟

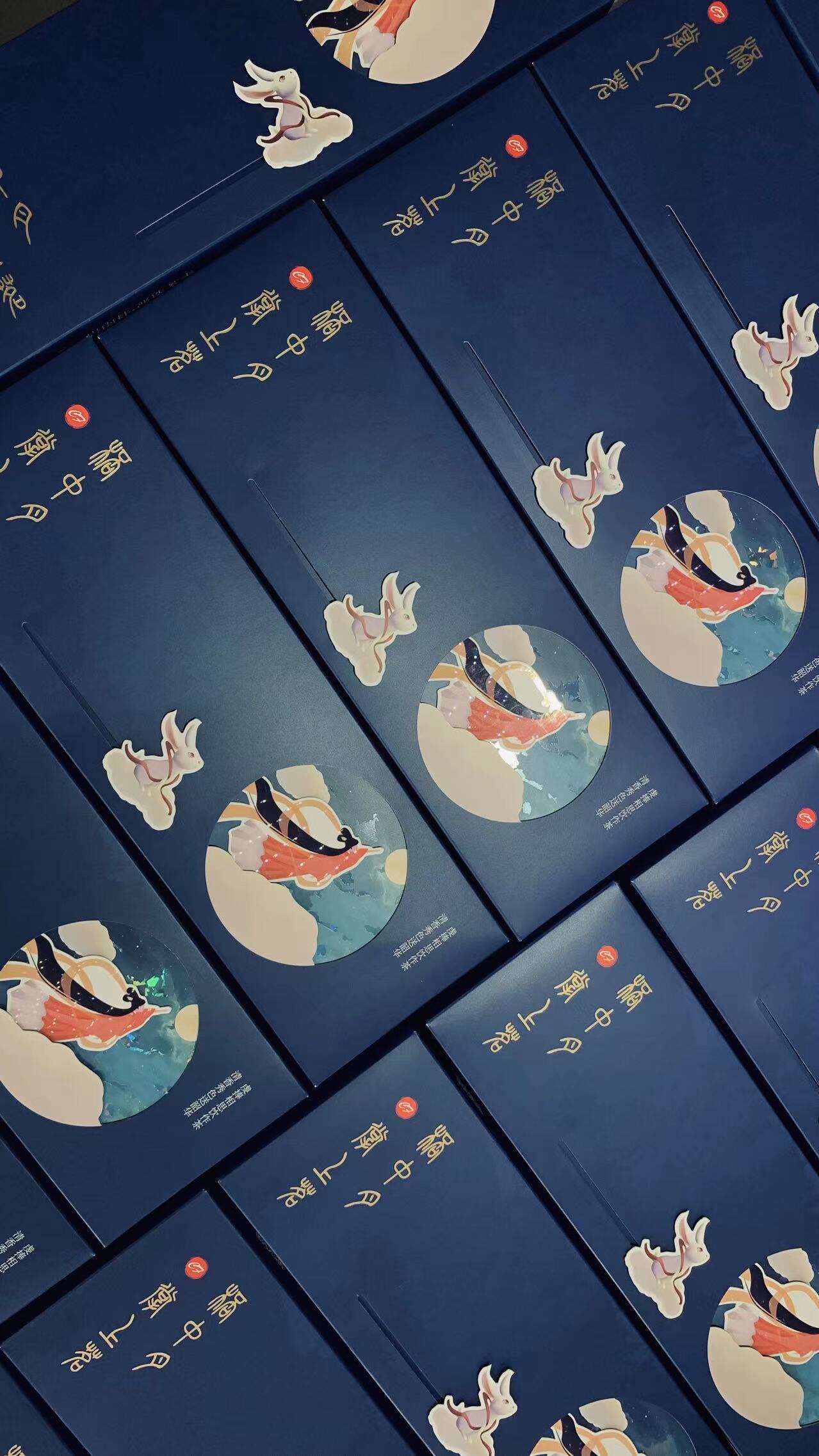

نقش جعبههای گل در بستهبندی لوکس آرایشی محبوبیت رو به افزایش طراحیهای گلی در برندینگ پremium افزایش داشته است زیرا این طراحیها هویت برند را تقویت و ارتباط عاطفی با مصرفکنندگان ایجاد میکند...

مشاهده بیشتر