սեփական մատուցիչական ընկերություններ

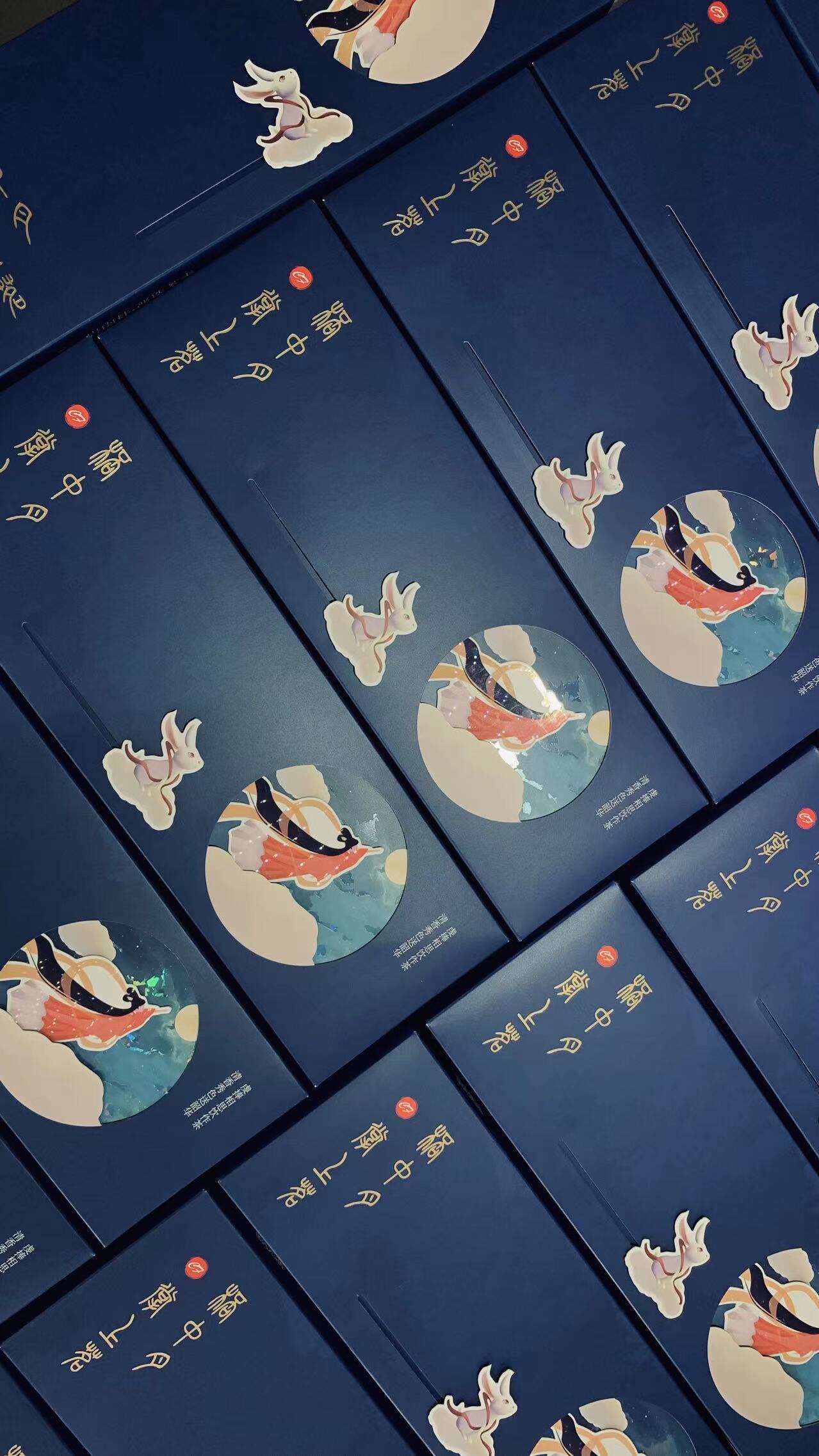

Անհատական փաթեթավորման ընկերությունները ծառայում են որպես մասնագիտացված մատակարարներ, որոնք նախագծում, արտադրում եւ մատակարարում են հարմարեցված փաթեթավորման լուծումներ տարբեր արդյունաբերությունների բիզնեսների համար: Այս կազմակերպությունները կենտրոնանում են եզակի փաթեթավորման փորձերի ստեղծման վրա, որոնք համապատասխանում են ապրանքանիշի ինքնությանը, արտադրանքի պահանջներին եւ շուկայական դիրքորոշման ռազմավարություններին: Անհատական փաթեթավորման ընկերությունները օգտագործում են առաջադեմ նախագծային ծրագրային ապահովում, գերժամանակակից տպագրական տեխնոլոգիաներ եւ ճշգրտ արտադրական սարքավորումներ, որպեսզի գաղափարական գաղափարները վերածեն հաստ փաթեթավորման լուծումների: Նրանց հիմնական գործառույթները ներառում են համապարփակ խորհրդատվական ծառայություններ, ստեղծագործական նախագծերի մշակում, նախատիպերի ստեղծում, նյութերի ընտրության ուղեցույց եւ ամբողջական արտադրության կառավարում: Այս ընկերությունները օգտագործում են թվային տպագրության համակարգեր, լազերային կտրող մեքենաներ, շերտավորման սարքավորումներ եւ ավտոմատացված հավաքման գծեր, որպեսզի ապահովեն մշտական որակ եւ արդյունավետ արտադրության ժամանակացույցներ: Տեխնոլոգիական ենթակառուցվածքը ներառում է համակարգչային աջակցությամբ նախագծման հարթակներ, գույնի կառավարման համակարգեր, որակի վերահսկման մեխանիզմներ եւ պաշարների հետեւման լուծումներ, որոնք բարելավում են փաթեթավորման զարգացման ամբողջ գործընթացը: Անհատականացված փաթեթավորման ընկերությունները ապահովում են տարբեր կիրառություններ, ներառյալ էլեկտրոնային առեւտրի առաքման տուփերը, մանրածախ արտադրանքի փաթեթավորումը, խթանման նվերների տուփերը, սննդի եւ խմիչքների բեռնարկղերը, կոսմետիկ փ Նրանց փորձը տարածվում է նաեւ բնական պաշարների այլընտրանքների վրա, որոնք ներառում են էկոլոգիապես մաքուր նյութեր եւ շրջակա միջավայրի չափանիշներին համապատասխանվող վերամշակվող բաղադրիչներ: Այս ընկերությունները համագործակցում են նորարարությունների, հաստատված ապրանքանիշերի եւ ձեռնարկությունների մակարդակի կազմակերպությունների հետ ՝ ստեղծելու հիշարժան unboxing փորձեր, որոնք բարձրացնում են հաճախորդների գոհունակությունը եւ ապրանքանիշի ճանաչումը: Խելացի փաթեթավորման տեխնոլոգիաների ինտեգրումը, ինչպիսիք են QR կոդերը, NFC չիպերը եւ ընդլայնված իրականության առանձնահատկությունները, ներկայացնում է ժամանակակից հարմարեցված փաթեթավորման ընկերությունների զարգացող կարողությունները: Նրանց համապարփակ մոտեցումը ներառում է շուկայական հետազոտությունների վերլուծություն, սպառողների վարքագծի պատկերացումներ եւ մրցակցային լանդշաֆտի գնահատում, որպեսզի ապահովեն փաթեթավորման լուծումների համահունչությունը թիրախային լսարանին ՝ միաժամանակ բավարարելով տարբեր աշխարհագրական շու