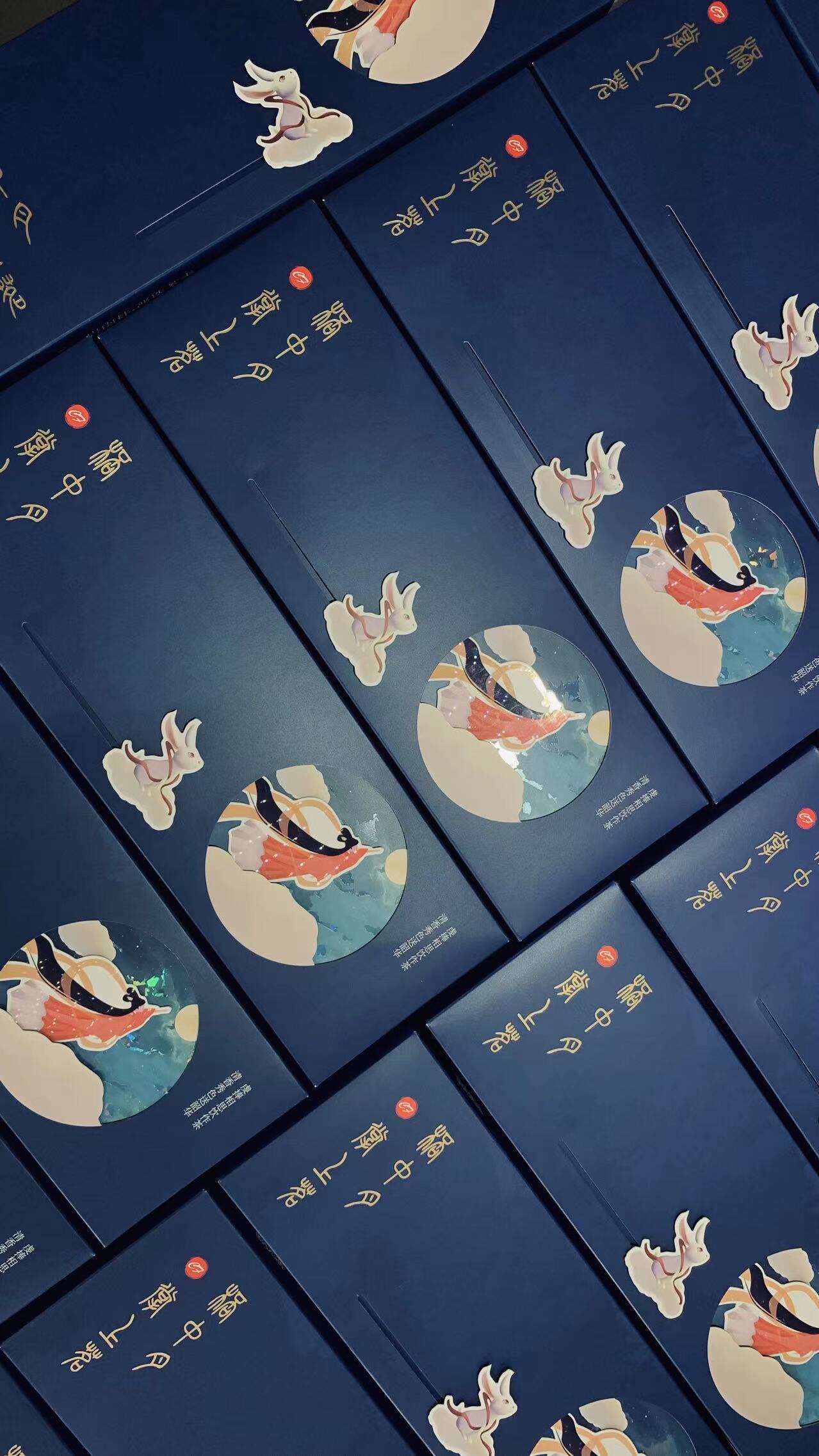

포장 맞춤화

포장 맞춤화는 표준 포장을 특정 브랜드 요구사항과 제품 특성에 부합하는 맞춤형 마케팅 도구이자 기능적 디자인으로 전환하는 종합적인 솔루션을 의미합니다. 이 혁신적인 접근법은 단순한 제품 보호를 넘어서는 다양한 목적을 달성하는 독특한 포장 솔루션의 기획, 제조 및 생산 전 과정을 아우릅니다. 최신 포장 맞춤화는 첨단 인쇄 기술, 지속 가능한 소재 및 최첨단 설계 소프트웨어를 활용하여 브랜드 가시성을 강화하고, 고객 경험을 개선하며, 공급망 효율성을 최적화하는 차별화된 패키지를 제작합니다. 포장 맞춤화의 핵심 기능에는 시각적 정체성 통합을 통한 브랜드 차별화, 공학적 소재와 구조 설계를 통한 제품 보호, 인터랙티브 요소와 프리미엄 미감을 통한 소비자 참여 유도가 포함됩니다. 오늘날 포장 맞춤화를 주도하는 기술적 요소로는 소량 생산이 가능한 디지털 인쇄 기술, 신속한 프로토타입 제작을 지원하는 컴퓨터 보조 설계 시스템, 정밀한 제조를 보장하는 자동 절단 및 접힘 장비, QR 코드, NFC 칩, 온도 센서 등을 통합하는 스마트 포장 기술 등이 있습니다. 소재 혁신 또한 중요한 역할을 하며, 생분해성 플라스틱과 재활용 골판지에서부터 금속 마감 처리 및 질감 있는 표면과 같은 고급 소재까지 다양한 선택지를 제공합니다. 적용 분야는 특별한 언박싱 경험을 추구하는 이커머스 기업부터 특수 보호 포장이 필요한 제약 회사에 이르기까지 다양한 산업 전반에 걸쳐 있습니다. 식음료 업계는 계절 한정 판매나 기간 한정 출시 제품에 포장 맞춤화를 활용하며, 명품 제조업체는 프리미엄 포장을 통해 브랜드 입지를 강화합니다. 이 과정은 일반적으로 상담 및 디자인 컨셉 수립으로 시작되어 소재 선정, 프로토타입 개발, 테스트 단계, 최종 양산 확대로 이어집니다. 품질 관리 조치를 통해 대량 생산 시 일관성을 확보하며, 물류 조정을 통해 적시 납품이 보장됩니다. 이러한 종합적인 접근 방식 덕분에 포장 맞춤화는 경쟁 시장에서 제품 차별화를 추구하면서도 운영 효율성과 환경적 책임을 유지하려는 기업들에게 필수적인 전략이 되었습니다.