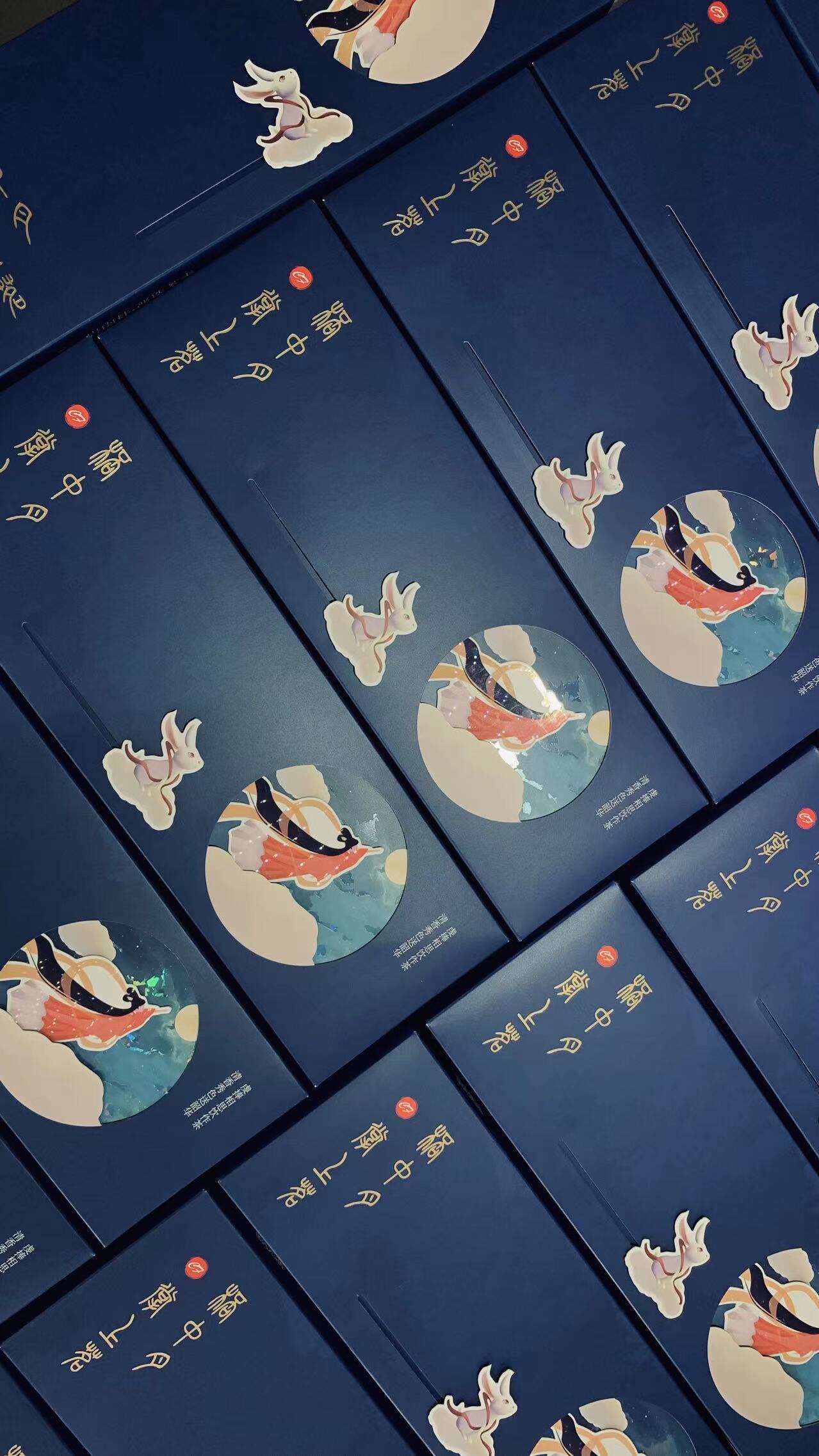

pakuotės su tinkamu dizainu

Įprastos pakuotės maišeliai yra revoliucinis produktų pakuočių metodas, kuris jungia lankstumą, apsaugą ir prekės ženklo atpažinimą į vieną universalų sprendimą. Šie specialiai įrengti konteinerai yra sukurti siekiant atitikti konkrečius įvairių pramonės šakų reikalavimus, siūlydami pritaikytus matmenis, medžiagas ir dizaino elementus, kurių negali suteikti standartinės pakuotės. Pagrindinė užsakomųjų pakuočių maišelių funkcija yra užtikrinti aukštesnę produktų apsaugą, išlaikant optimalų šviežumą, pratęsiant laikymo laiką ir užkertant kelią užteršimui pažangiomis barjerinėmis technologijomis. Šiuose maišuose naudojami daugiasluoksnūs konstrukciniai metodai, kuriuose naudojamos skirtingos medžiagos, tokios kaip polietilenas, polipropilenas, aliuminio folija ir specializuotos barjerinės plėvelės, siekiant sukurti neprieinamą uždėtį nuo drėgmės, deguonies, šviesos ir kitų aplinkos veiks Technologijos savybės apima šilumos uždarymo galimybes, atsparus ašaroms medžiagas, nepertraukiamą konstrukciją ir pasirinktinį uždarymą, kuris palengvina naudotojo patogumą. Įžangios spausdinimo technologijos leidžia sukurti aukštos skiriamumo grafiką, ryškias spalvas ir tikslius prekės ženklų elementus, kurie leidžia prekėms išsiskirti parduotuvių lentynose. Daugelyje užsakomųjų pakuočių maišelių yra naujoviškų funkcijų, tokių kaip skystųjų produktų spynos, produktų matomumo langai, mažmeninės prekybos ekranų dangos ir lengvai atveriami mechanizmai vartotojams patogumui. Naudojimas apima daugybę pramonės šakų, įskaitant maisto ir gėrimų, farmacijos, kosmetikos, augintinių maisto, žemės ūkio produktų ir pramonės medžiagų. Maisto sektoriuje šie maišeliai saugo užkandžius, kavą, džiovintus vaisius ir paruoštus patiekalus, išlaikydami maistinę vertę ir skonį. Farmacijos srityje naudojamos pakuotės, skirtos papildams, milteliams ir medicinos prietaisams, kuriuose svarbiausia yra sterilumas ir užterštumo prevencija. Kosmetikos pramonė naudoja specialius pakuočių maišelius mėginiams, kelionių produktui ir daugeliui ingredientų. Žemės ūkio įmonės naudojasi šiais sprendimais sėkloms, trąšoms ir gyvūnų pašarų saugojimui. Įprastų pakuočių maišelių įvairovė leidžia jiems idealiai naudoti tiek mažų amatų produktus, tiek didelių komercinių operacijų metu, teikiant skaliuojamus sprendimus, kurie auga atsižvelgiant į verslo poreikius.