individuota ambalio pakardžio

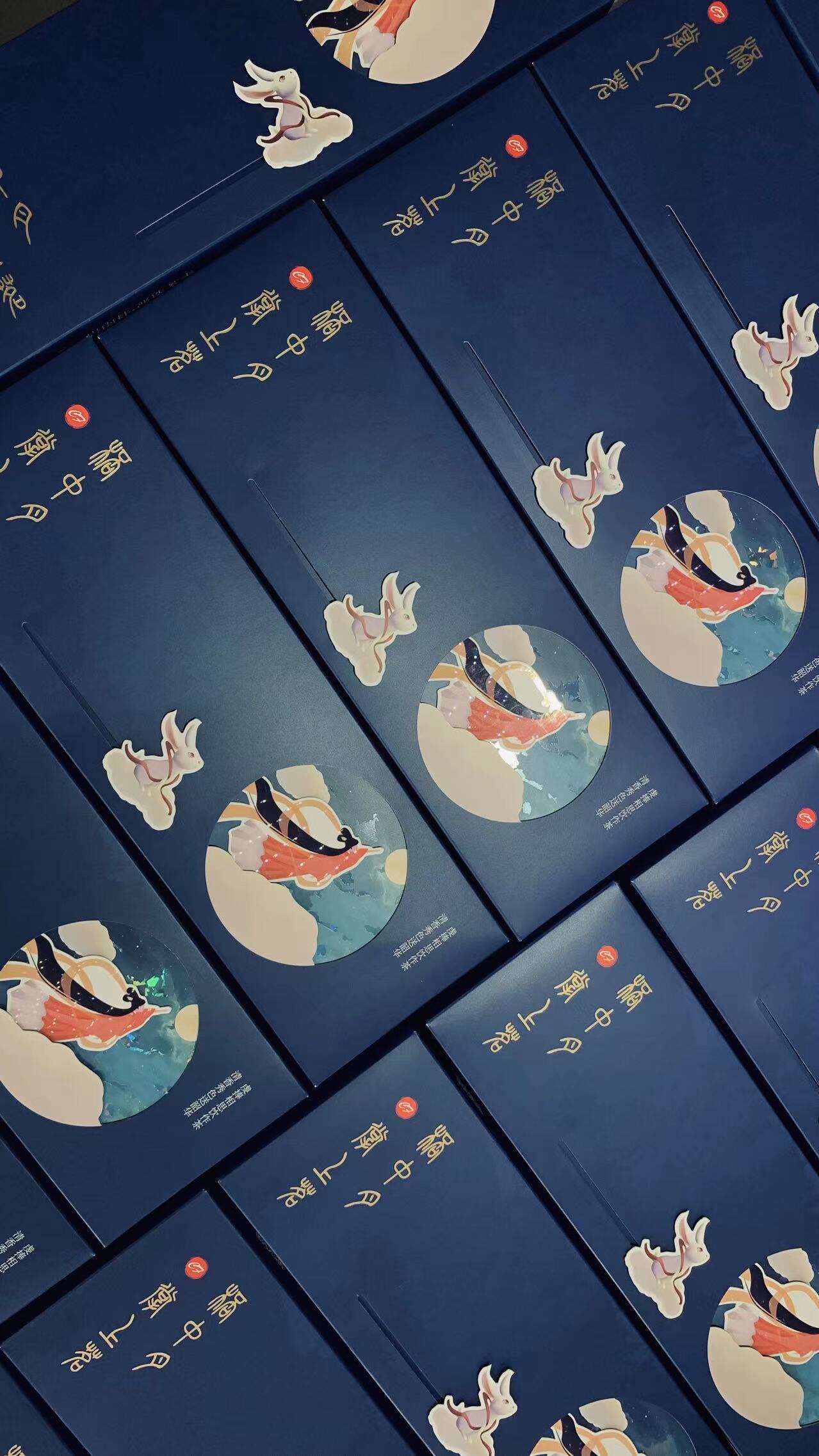

Pakavimo pritaikymas atstovauja visapusiškam sprendimui, kuris standartinį pakavimą paverčia individualiais rinkodaros įrankiais ir funkcionaliais dizainais, atitinkančiais specifinius prekių ženklų reikalavimus ir produkto savybes. Šis inovatyvus požiūris apima visą unikalių pakavimo sprendimų kūrimo, gamybos ir gamybos procesą, turintį daugiau nei tik pagrindinę produkto apsaugos funkciją. Šiuolaikinis pakavimo pritaikymas pasitelkia pažangias spausdinimo technologijas, tvarius medžiagas ir naujausios kartos dizaino programinę įrangą, kad būtų sukuriami išskirtiniai paketai, padidinantys prekių ženklo matomumą, gerinantys klientų patirtį ir optimizuojant tiekimo grandinės veikimą. Pagrindinės pakavimo pritaikymo funkcijos apima prekių ženklo diferenciaciją per vizualinės tapatybės integraciją, produkto apsaugą naudojant inžinerines medžiagas ir struktūrinį dizainą bei vartotojų įtraukimą per interaktyvius elementus ir aukštos kokybės estetiką. Technologiniai bruožai, skatinantys šiandieninį pakavimo pritaikymą, apima skaitmeninio spausdinimo galimybes, leidžiančias trumpoms serijoms, kompiuterinio projektavimo sistemas, palengvinančias greitą prototipavimą, automatizuotas pjaustymo ir lankstymo mašinas, užtikrinančias tikslų gamybą, bei „išmanųjį“ pakavimą, integruojantį QR kodus, NFC čipsus ir temperatūros jutiklius. Medžiagų inovacijos atlieka svarbų vaidmenį, siūlydamos pasirinkimus nuo biodegraduojamų plastikų ir perdirbto kartono iki aukštos kokybės medžiagų, tokių kaip metalizuoti paviršiai ir reljefūs tekstūrizuoti paviršiai. Taikymo sritys apima daugelį pramonės šakų – nuo elektroninės prekybos įmonių, siekiančių nepaprastų atvyniojimo patirčių, iki farmacijos įmonių, reikalaujančių specializuoto apsauginio pakavimo. Maisto ir gėrimų sektoriai naudoja pakavimo pritaikymą sezoniniams reklaminiams akcijoms ir ribotų leidžiamų serijų pristatymui, tuo tarpu prabangaus segmento gamintojai priklauso nuo aukštos kokybės pakavimo, norėdami sustiprinti savo prekių ženklo poziciją. Procesas paprastai prasideda konsultacija ir dizaino koncepcijos sukūrimu, po to sekasi medžiagų atranka, prototipo kūrimas, testavimo etapai ir galutinis gamybos mastelio didinimas. Kokybės kontrolės priemonės užtikrina vientisumą visose gamybos serijose, o logistikos koordinavimas garantuoja laiku pristatymą. Toks visapusiškas požiūris daro pakavimo pritaikymą būtinu strateginiu sprendimu įmonėms, siekiančioms išskirti savo produktus konkurencingose rinkose, išlaikant operacinį efektyvumą ir aplinkosaugos atsakomybę.