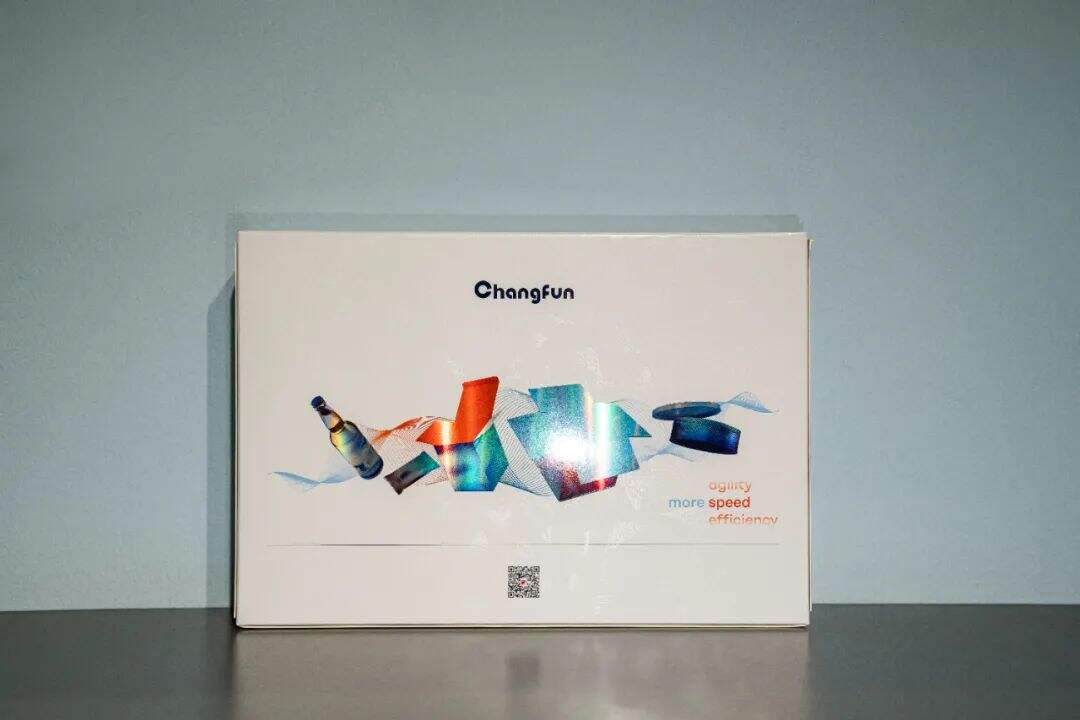

Wyjątkowa jakość druku i odtwarzanie szczegółów

Najlepsze kolorowe drukowanie offsetowe osiąga wyjątkową jakość druku i reprodukcję szczegółów, która przewyższa inne technologie drukowania komercyjnego, czyniąc ją preferowaną metodą w zastosowaniach wymagających wysokiego wpływu wizualnego i profesjonalnego wyglądu. Ta nadzwyczajna jakość wynika z precyzyjnego mechanizmu przenoszenia farby, który tworzy ostre, czyste obrazy z niezwykłym zachowaniem szczegółów i płynnymi przejściami tonalnymi. Pośredni proces drukowania stosowany w technologii offsetowej zapobiega bezpośredniemu kontaktowi form drukowych z podłożem, eliminując ślady odciśnięć i zapewniając spójne pokrycie farbą całej powierzchni drukowanej. Możliwości wysokorozdzielczych systemów wizyjnych pozwalają na uchwycenie drobnych szczegółów, małych tekstów i skomplikowanych elementów projektowych z niezwykłą wyrazistością, dając efekty profesjonalne, które poprawiają postrzeganie marki i skuteczność działań marketingowych. Najlepsze kolorowe drukowanie offsetowe obsługuje siatki linii do 300 linii na cal, umożliwiając reprodukcję obrazów fotograficznych z gładkimi gradientami i wyjątkową szczegółowością, która konkurować może z tradycyjnymi metodami druku fotograficznego. Zaawansowane technologie rastrów, w tym rastry stochastyczne, eliminują wzory moiré i struktury różyczkowe, tworząc czystsze obrazy z lepszą szczegółowością w cieniach i świetlach. Precyzyjne systemy rejestracji utrzymują dokładne wyrównanie pomiędzy wieloma oddzieleniami kolorów, zapewniając ostre krawędzie tekstu i eliminując rozmycie kolorów, które może naruszać profesjonalny wygląd. Technologia ta obsługuje różne typy farb, w tym konwencjonalne, utwardzane UV oraz specjalistyczne, które zapewniają zwiększoną trwałość, odporność na zarysowania i ochronę przed wypłowieniem, co gwarantuje długotrwałą jakość materiałów drukowanych. Doskonałe cechy formowania kropek wynikają zoptymalizowanego ciśnienia drukowania i kontroli lepkości farby, które produkują jednolite, dobrze zdefiniowane kropki rastrowe niezbędne do wysokiej jakości reprodukcji obrazu. Najlepsze systemy kolorowego druku offsetowego wykorzystują zaawansowane systemy zwilżania, które utrzymują optymalny balans między farbą a wodą, zapobiegając problemom takim jak smarowanie, zabarwienie czy słabe przenoszenie farby, które mogą naruszyć jakość druku. Precyzyjnie zaprojektowane walce i wysokiej jakości narzuty zapewniają spójne ciśnienie odciśnięcia na całej szerokości arkusza, eliminując wariacje gęstości i utrzymując jednolitą jakość druku od krawędzi do krawędzi. Systemy kontroli jakości ciągle monitorują różne parametry, w tym rejestację, gęstość koloru i kontrast druku, automatycznie dokonując korekt w celu utrzymania optymalnej jakości druku w całym cyklu produkcji.