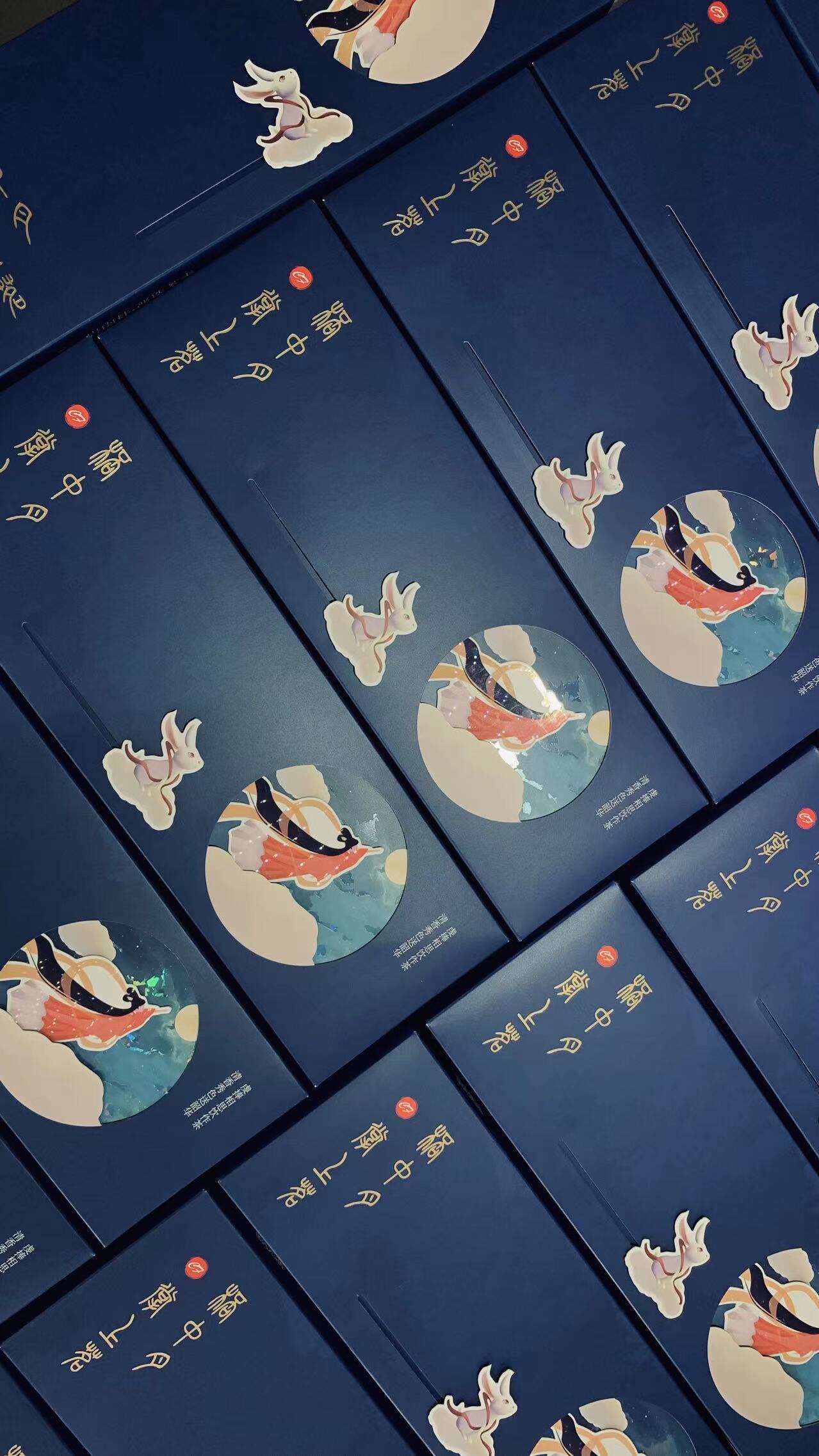

pappersask på beställning

Anpassade papperslåslösningar representerar en revolutionerande metod för förpackning som omvandlar vanliga wellpappmaterial till sofistikerade varumärkesverktyg och skyddande behållare. Denna innovativa förpackningsmetod kombinerar avancerad tryckteknik, precisionsstansning och strukturell ingenjörsdesign för att skapa skräddarsydda behållare som uppfyller specifika krav på dimensioner, estetik och funktion. Den anpassade processen för papperslådor inleds med en noggrann konsultation där designers analyserar produktspecifikationer, fraktbehov och varumärkesriktlinjer för att utveckla optimala förpackningslösningar. Modern tillverkning av anpassade papperslådor använder datorstödd designprogramvara, automatiserade skärningssystem och digitalt högupplöst tryck för att säkerställa konsekvent kvalitet och snabb produktion. Den tekniska grunden inkluderar avancerat litografiskt tryck, flexografiska processer och digitala bläckstrålesystem som levererar levande färger och skarpa grafiska motiv på olika pappersbaser. Anpassade papperslådlösningar innefattar strukturella innovationer såsom förstärkta hörn, sammanhängande mekanismer och specialkonstruerade lås som ökar hållbarheten utan att förlora kostnadseffektiviteten. Tillverkningsprocessen använder precisionsviktekniker, limapplikationer och kvalitetskontrollåtgärder som garanterar att varje enhet av anpassad papperslåda uppfyller strikta standarder. Tillämpningar finns inom många branscher, inklusive elektronik, kosmetika, livsmedel, läkemedel och e-handel, där anpassad papperslådeförpackning fyller dubbla syften: skydd och marknadsföring. Det detaljhandlade miljöer drar stora nytta av anpassade papperslådsdisplayer som lockar kundens uppmärksamhet samtidigt som de effektivt organiserar produkterna. Den anpassade papperslådens mångsidighet gör det möjligt att hantera olika produktformer, vikter och storlekar genom moduluppbyggda konstruktioner och adaptiva ingenjörsmetoder. Miljöhänsyn driver innovationer inom anpassade papperslådor mot hållbara material, biologiskt nedbrytbara färger och återvinningsbara komponenter som är i linje med företagens ansvarsinitiativ. Kvalitetssäkringsprotokoll säkerställer att anpassade papperslådor tål påfrestningar under transport, lagring och hantering längs hela distributionskedjan.