Çeşitli Malzeme Uyumluluğu ve İleri Sonlandırma Kapasitesi

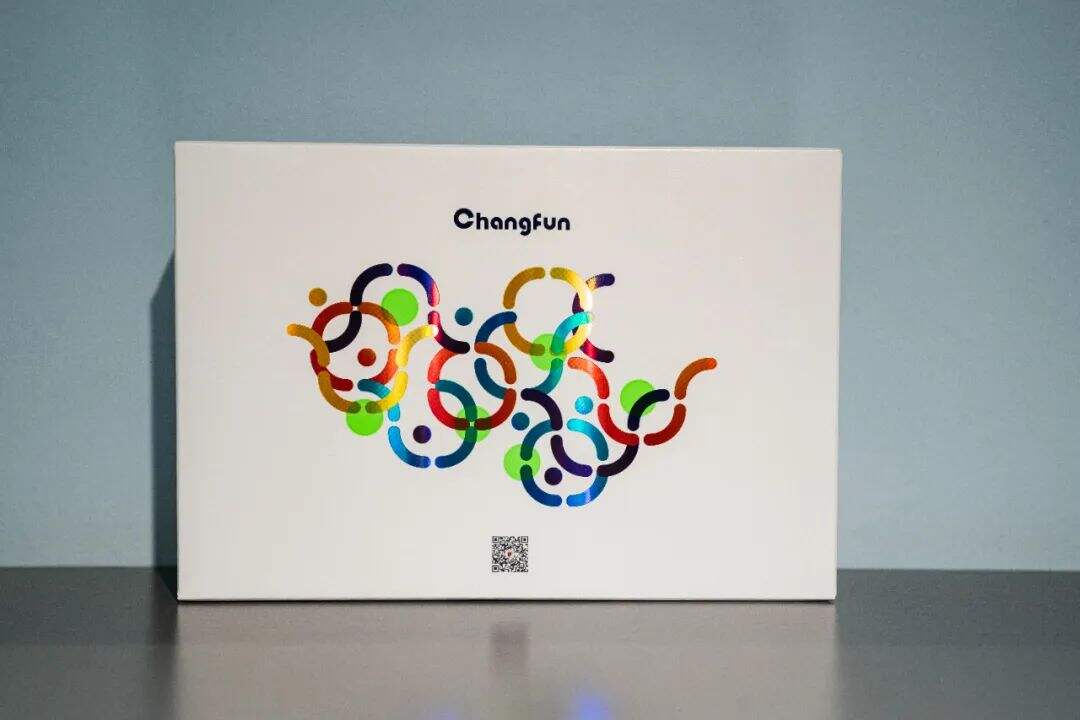

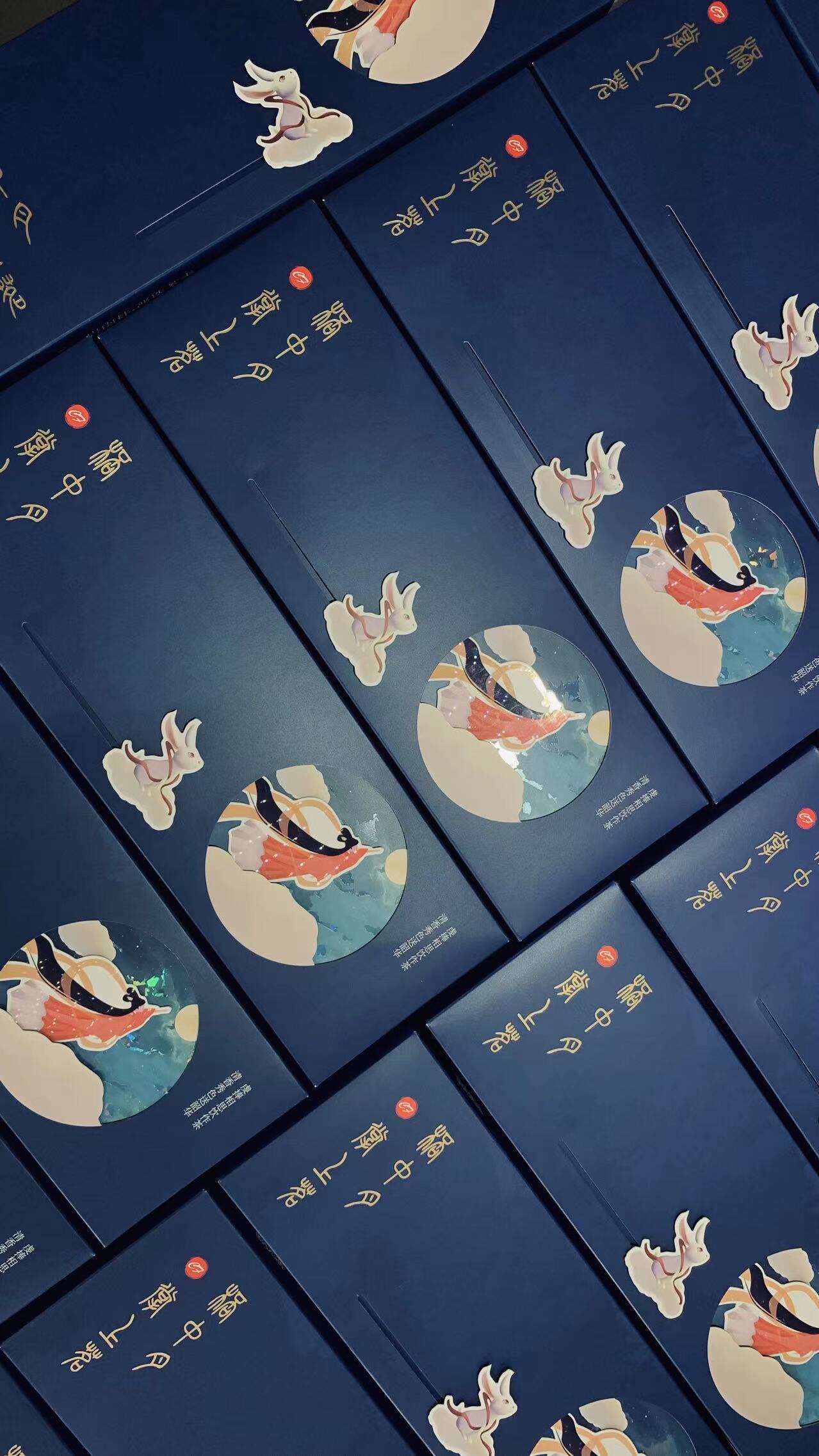

Dört renkli ofset baskı, çeşitli materyallerle uyumluluk ve sonlandırma seçeneklerinde dikkat çekici bir esneklik sunar ve bu sayede işletmeler, farklı uygulamalarda belirli işlevsel ve estetik gereksinimleri karşılayan çeşitli basılı materyaller oluşturabilir. Bu baskı teknolojisi, kaplamalı kâğıtlar, kaplamasız kâğıtlar, geri dönüştürülmüş malzemeler, sentetik altlıklar ve gıda ambalajları veya dış mekân dayanıklılığı gibi özel uygulamalar için tasarlanmış özel kâğıtlar dahil olmak üzere geniş bir kâğıt ağırlığı, dokusu ve özel altlık yelpazesini destekler. Dört renkli ofset baskının esnekliği, yüksek hacimli posta gönderimleri için uygun hafif 70 g/m² kâğıtlardan, premium sunum materyalleri ve ambalaj uygulamaları için uygun ağır 350 g/m² kartonlara kadar değişen çeşitli kâğıt ağırlıklarını kapsar. Bu altlık çeşitliliği, işletmelerin proje bütçeleri, çevresel hususlar ve işlevsel gereksinimlerle uyumlu malzemeler seçmesine olanak tanır ve bunu yaparken baskı kalitesi veya görsel çekicilikten ödün vermeden sağlar. Dört renkli ofset baskı ayrıca pazarlama uygulamaları için yaratıcı imkânları genişleten metalize kâğıtlar, doku yüzeyler ve su geçirmez malzemeler gibi özel altlıkları da destekler. Teknoloji, spot UV kaplama, aköz kaplama, lamine etme, kabartma, çökertme, folyo baskı ve die-cut (kalıp kesimi) işlemlerini içeren ve basılı materyallerin işlevselliğini ile estetik çekiciliğini artıran çeşitli sonlandırma tekniklerini de destekler. Bu sonlandırma seçenekleri, işletmelerin premium kalite ve detaylara özen gösterdiğini yansıtan özgün basılı ürünler oluşturmasını sağlar ve markaların rekabetçi pazarlarda kendilerini ayırt etmelerine yardımcı olur. Dört renkli ofset baskı, birden fazla sonlandırma tekniğinin koordineli üretim süreçleri içinde verimli bir şekilde uygulanmasına olanak tanıyan posta baskı işlemleriyle sorunsuz bir şekilde entegre olur. Dört renkli ofset baskının hassasiyeti, karmaşık sonlandırma işlemlerinden sonra bile bitmiş ürünlerin doğru kayıt ve hizalamayı korumasını sağlayarak tüm üretim süreci boyunca tasarım bütünlüğünü korur. Bu yetenek, basılı unsurlar ile sonlandırma işlemleri arasında tam kayıt gerektiren, hassas die-cut kesim, skorlama ve katlama gereksinimlerine sahip ambalaj uygulamalarında özellikle değerlidir. Altlık esnekliğinin ve sonlandırma özelliklerinin birleşimi, dört renkli ofset baskıyı basit iş iletişiminden özel malzemeler ve karmaşık sonlandırma ayrıntıları gerektiren gelişmiş ambalaj çözümlerine kadar çeşitli uygulamalar için uygundur.