The packaging industry has witnessed remarkable advancements in printing technologies, with offset printing emerging as the gold standard for producing high-quality paper boxes that demand exceptional detail and vibrant color reproduction. This sophisticated printing method has revolutionized how brands present their products, particularly in sectors where visual appeal directly influences consumer purchasing decisions. The precision and consistency offered by offset printing paper boxes make them ideal for luxury goods, cosmetics, electronics, and premium food products where every visual element must convey quality and professionalism.

Modern businesses increasingly recognize that packaging serves as a silent salesperson, often determining whether a customer chooses their product over competitors. The intricate details achievable through offset printing technology enable brands to incorporate complex designs, subtle gradients, and microscopic text elements that maintain clarity even under close examination. This capability becomes particularly crucial when dealing with regulatory information, ingredient lists, or intricate brand logos that must remain legible while contributing to the overall aesthetic appeal of the packaging.

The offset printing process relies on a sophisticated plate-based system that transfers ink from printing plates to rubber blankets before applying it to the paper substrate. This indirect printing method allows for exceptional control over ink distribution and enables the production of offset printing paper boxes with remarkable consistency across large print runs. The aluminum or polyester plates used in this process are treated with photosensitive coatings that create distinct hydrophilic and hydrophobic areas, ensuring precise ink adhesion only where intended.

Each color in the printing process requires its own dedicated plate, with most commercial applications utilizing the CMYK color model consisting of cyan, magenta, yellow, and black plates. The precision engineering of these plates allows for dot patterns as fine as 200 lines per inch or higher, creating smooth color transitions and enabling the reproduction of photographic images with exceptional clarity. This level of detail proves essential when manufacturing premium packaging that must showcase product imagery or complex brand elements with professional quality.

The specialized inks used in offset printing paper boxes contain carefully balanced formulations of pigments, resins, and additives that ensure optimal adhesion to various paper substrates while maintaining color accuracy throughout the printing process. These inks are designed to work within specific viscosity ranges and drying characteristics that complement the mechanical aspects of offset printing equipment. The pigment concentration in offset inks typically exceeds that found in other printing methods, contributing to the intense color saturation achievable in finished packaging products.

Color management systems integrated into modern offset printing operations utilize spectrophotometers and densitometers to monitor and adjust color reproduction in real-time. This technological integration ensures that offset printing paper boxes maintain consistent color profiles throughout production runs, regardless of environmental conditions or equipment variations. The ability to achieve and maintain color accuracy becomes particularly important for brands with established color identities, where even minor variations could compromise brand recognition and consumer trust.

The exceptional detail capabilities of offset printing paper boxes stem from advanced halftone screening technologies that break down continuous-tone images into patterns of tiny dots that create the illusion of smooth color gradations when viewed at normal distances. Modern screening techniques utilize stochastic or frequency-modulated screening methods that randomize dot placement, eliminating the moiré patterns that can occur with traditional screening approaches. This technology enables the reproduction of fine textures, subtle shadows, and intricate details that would be impossible to achieve with other printing methods.

The dot gain characteristics of offset printing are precisely controlled through careful management of ink viscosity, printing pressure, and paper absorption rates. Professional offset printing operations typically achieve dot gain values between 10-20%, which allows for predictable color reproduction and ensures that fine details remain sharp and well-defined. This level of control becomes essential when printing offset printing paper boxes that incorporate small text, detailed illustrations, or complex patterns that must remain legible and visually appealing throughout the product's shelf life.

Multi-color offset printing requires exceptional registration accuracy to ensure that different color layers align perfectly, creating crisp edges and preventing color fringing that could compromise the professional appearance of finished packaging. Modern offset printing presses utilize automated registration systems that can maintain alignment tolerances within 0.05 millimeters, ensuring that even the most complex designs reproduce with precision. This accuracy proves crucial for offset printing paper boxes that feature intricate borders, fine line work, or overlapping design elements.

The mechanical stability of offset printing equipment contributes significantly to maintaining consistent registration throughout long production runs. Heavy-duty press construction minimizes vibration and thermal expansion that could affect print registration, while sophisticated feeding systems ensure consistent paper positioning for each impression. These factors combine to enable the production of offset printing paper boxes with uniform quality that meets the exacting standards required for premium packaging applications.

While traditional four-color offset printing provides excellent color reproduction for most applications, extended color gamut printing techniques expand the range of achievable colors by incorporating additional ink colors such as orange, green, or violet. These expanded color systems enable offset printing paper boxes to reproduce colors that fall outside the standard CMYK gamut, particularly vibrant oranges, deep blues, and rich purples that are often crucial for brand identity and product appeal. The additional color stations required for extended gamut printing represent a significant investment but deliver unmatched color fidelity for premium packaging applications.

The color matching capabilities of extended gamut systems often exceed 95% of Pantone colors, providing brands with confidence that their specific color requirements will be met with exceptional accuracy. This capability becomes particularly important for consumer goods packaging where color consistency across different production runs and geographic locations is essential for maintaining brand integrity. The investment in extended color gamut technology pays dividends through reduced color matching iterations and improved customer satisfaction with the final packaging appearance.

The flexibility of offset printing technology allows for seamless integration of spot colors alongside process colors, enabling offset printing paper boxes to incorporate specific brand colors that require exact matching. Spot colors are mixed according to precise formulas using standardized color systems such as Pantone, ensuring consistent reproduction across different printing facilities and production runs. This capability proves essential for brands with established color identities that cannot be accurately reproduced using process color combinations alone.

The ink layering possibilities in offset printing enable sophisticated color effects through the strategic use of spot colors in combination with process colors. Techniques such as building spot colors over process color foundations can create unique color depths and visual effects that enhance the premium appearance of packaging. These advanced color applications require skilled press operators and precise color management but result in offset printing paper boxes that stand out on retail shelves and reinforce brand positioning.

The success of offset printing paper boxes depends heavily on the selection and preparation of appropriate paper substrates that complement the printing process requirements. Coated papers provide smooth, uniform surfaces that minimize ink absorption and enable sharp detail reproduction, while uncoated papers offer different aesthetic qualities and may be preferred for certain applications despite their higher ink absorption characteristics. The surface energy of the paper substrate must be compatible with the ink chemistry to ensure proper adhesion and prevent issues such as picking or offsetting during the printing process.

Paper caliper and formation consistency directly impact print quality, with variations in thickness or density causing registration problems and uneven ink distribution. High-quality papers manufactured specifically for offset printing applications undergo rigorous quality control procedures to ensure consistent formation, moisture content, and surface characteristics that support optimal printing results. The selection of appropriate paper grades for offset printing paper boxes requires careful consideration of both printing requirements and end-use performance characteristics such as folding strength, tear resistance, and dimensional stability.

Post-printing coating applications can significantly enhance the visual appeal and durability of offset printing paper boxes while protecting the printed surface from scuffing, moisture, and other environmental factors. Aqueous coatings provide cost-effective protection with minimal impact on recycling processes, while UV coatings offer superior durability and can create striking visual effects through the use of textured or specialty formulations. The compatibility between printing inks and coating systems requires careful coordination to prevent adhesion problems or color shifts that could compromise the final appearance.

Spot coating applications enable selective enhancement of specific design elements, creating visual hierarchy and tactile interest that enhances the unboxing experience for consumers. These targeted applications can highlight product imagery, brand logos, or text elements while leaving other areas uncoated for different visual or functional properties. The precision required for spot coating applications aligns well with the accuracy capabilities of offset printing paper boxes production, creating opportunities for sophisticated packaging designs that combine multiple surface treatments effectively.

Professional offset printing operations implement comprehensive color management systems that utilize advanced instrumentation to monitor and control color reproduction throughout the production process. Spectrophotometers and densitometers provide objective measurements that eliminate subjective color evaluation, ensuring that offset printing paper boxes maintain consistent appearance regardless of lighting conditions or individual perception differences. These measurement systems typically operate within tolerance ranges of delta E values less than 2.0, representing color differences that are virtually imperceptible to the human eye under normal viewing conditions.

Process standardization initiatives such as G7 methodology provide frameworks for achieving consistent color reproduction across different printing facilities and equipment configurations. These standardized approaches define specific measurement procedures, calibration requirements, and quality control protocols that ensure offset printing paper boxes produced at different locations or times maintain identical visual characteristics. The implementation of these standards requires significant investment in training and equipment but delivers measurable improvements in quality consistency and customer satisfaction.

Continuous monitoring systems integrated into modern offset printing presses provide real-time feedback on print quality parameters, enabling immediate adjustments to maintain optimal printing conditions throughout production runs. These systems monitor factors such as ink density, registration accuracy, and dot gain characteristics, automatically adjusting press settings to maintain target specifications. The ability to detect and correct quality deviations in real-time prevents the production of defective offset printing paper boxes and minimizes waste while ensuring consistent output quality.

Statistical process control methods applied to offset printing operations track quality metrics over time, identifying trends that could indicate developing problems or opportunities for process improvement. This data-driven approach to quality management enables printing facilities to optimize their processes continuously and achieve higher levels of consistency in offset printing paper boxes production. The historical data collected through these monitoring systems also supports customer quality claims and provides valuable insights for future process optimization initiatives.

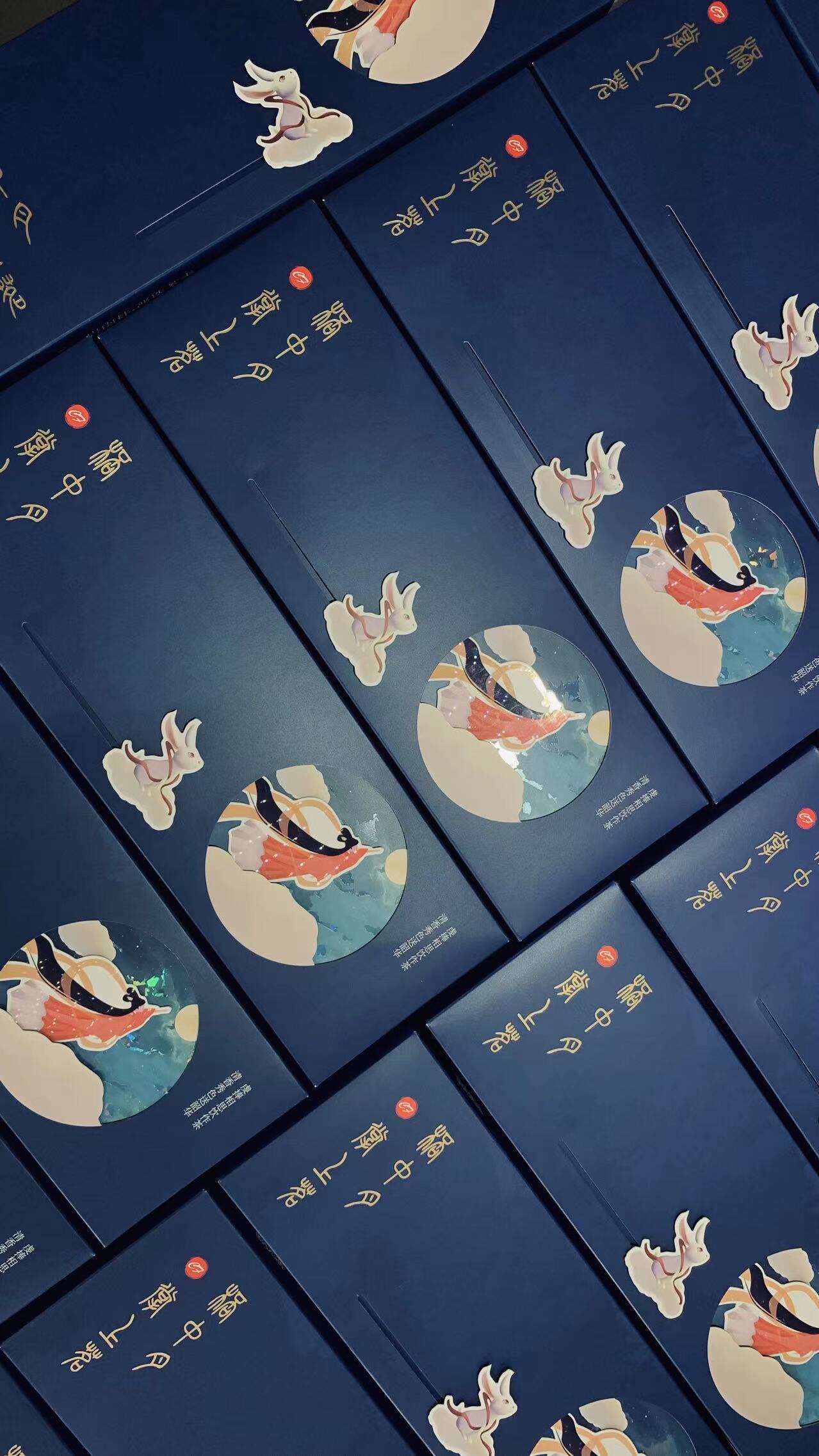

The luxury goods sector represents one of the most demanding applications for offset printing paper boxes, where exceptional print quality directly correlates with perceived product value and brand positioning. High-end cosmetics, jewelry, and fashion accessories require packaging that reflects their premium positioning through sophisticated graphics, precise color reproduction, and flawless execution of complex design elements. The ability of offset printing to reproduce fine details such as embossed textures, metallic accents, and subtle color variations makes it the preferred choice for brands seeking to create memorable unboxing experiences that reinforce their premium positioning.

The food and beverage industry also benefits significantly from the capabilities of offset printing paper boxes, particularly for products where appetite appeal depends on accurate color reproduction of food imagery. Chocolate manufacturers, gourmet food producers, and craft beverage companies utilize offset printing to showcase their products with photographic quality that entices consumers and differentiates their offerings from competitors. The food-safe ink formulations available for offset printing ensure compliance with regulatory requirements while maintaining the visual impact necessary for retail success.

Industries with extensive regulatory requirements, such as pharmaceuticals and medical devices, rely on offset printing paper boxes to reproduce complex technical information with absolute clarity and accuracy. Regulatory text, dosage instructions, and warning labels must remain legible throughout the product's shelf life while meeting specific font size and contrast requirements mandated by regulatory authorities. The precision capabilities of offset printing ensure that even the smallest text remains sharp and readable, supporting compliance with international packaging regulations.

The ability to integrate multiple languages and complex formatting requirements makes offset printing paper boxes ideal for products distributed across international markets. The consistent reproduction capabilities of offset printing ensure that regulatory information maintains identical appearance across different production locations, supporting global brand consistency while meeting local regulatory requirements. This capability becomes increasingly important as companies expand their market reach and face diverse regulatory environments in different regions.

The economic advantages of offset printing become particularly apparent in medium to large production runs where the fixed costs associated with plate preparation and press setup are distributed across thousands or tens of thousands of units. The high-speed capabilities of modern offset printing presses enable rapid production of offset printing paper boxes with minimal per-unit labor costs, making this technology cost-effective for most commercial packaging applications. The durability of printing plates allows for reprinting of successful designs without additional plate costs, supporting efficient inventory management and reducing lead times for repeat orders.

Waste reduction initiatives in offset printing operations focus on optimizing sheet utilization through efficient layout planning and minimizing startup waste through improved press setup procedures. Modern press controls enable faster achievement of target color densities and registration accuracy, reducing the number of sheets required to reach production standards. These efficiency improvements translate directly into cost savings and environmental benefits while maintaining the high quality standards expected from offset printing paper boxes production.

Environmental considerations play an increasingly important role in packaging decisions, with offset printing technology offering several advantages in terms of sustainability and recyclability. The vegetable-based inks commonly used in offset printing paper boxes production break down more readily during the recycling process compared to other ink systems, supporting circular economy initiatives and reducing environmental impact. Water-based coatings and alcohol-free printing processes further minimize the environmental footprint of offset printing operations while maintaining quality standards.

The longevity and efficiency of offset printing equipment contribute to reduced resource consumption over the life cycle of printing operations. Modern presses require less energy per impression compared to other printing technologies and generate less waste through improved process control and automation. These factors combine to make offset printing paper boxes an environmentally responsible choice for brands seeking to minimize their packaging-related environmental impact while maintaining high quality standards.

The integration of digital technologies with traditional offset printing processes creates new possibilities for customization and efficiency in offset printing paper boxes production. Hybrid workflows that combine the quality advantages of offset printing with the flexibility of digital imaging enable variable data printing applications where individual packages can include personalized elements while maintaining the consistent high quality of offset printing for primary design elements. These capabilities support marketing initiatives that require personalized packaging while preserving the economic advantages of offset printing for base production.

Advanced color management systems increasingly utilize artificial intelligence and machine learning algorithms to optimize color reproduction and predict quality outcomes before production begins. These systems analyze historical data and current operating conditions to recommend optimal press settings and ink formulations for specific jobs, reducing setup time and improving first-pass quality rates. The evolution of these technologies promises to further enhance the capabilities and efficiency of offset printing paper boxes production while maintaining the exceptional quality standards that define this printing method.

Ongoing developments in ink chemistry and paper substrate technology continue to expand the capabilities of offset printing paper boxes while addressing environmental and performance requirements. Bio-based ink formulations derived from renewable resources offer reduced environmental impact without compromising color quality or durability, supporting brand sustainability initiatives. Advanced paper treatments and coatings provide enhanced barrier properties and durability while maintaining compatibility with offset printing processes and recycling systems.

Nanotechnology applications in offset printing materials promise to deliver enhanced performance characteristics such as antimicrobial properties, improved moisture resistance, and extended color stability. These advanced materials maintain compatibility with existing offset printing equipment while providing additional functionality that can differentiate packaging products and support brand positioning. The continued evolution of materials science ensures that offset printing paper boxes will continue to meet evolving market requirements while maintaining their reputation for exceptional quality and reliability.

Offset printing delivers superior color consistency, finer detail resolution, and better ink opacity compared to digital printing methods. The plate-based process enables precise dot placement and consistent ink distribution across large production runs, while the specialized inks provide deeper color saturation and better adhesion to various paper substrates. For production runs exceeding 1,000 units, offset printing typically offers better cost-effectiveness while maintaining exceptional quality standards that meet premium packaging requirements.

Paper substrate characteristics directly impact print quality, with factors such as surface smoothness, absorption rate, and formation consistency affecting ink transfer and detail reproduction. Coated papers provide optimal surfaces for fine detail reproduction and color accuracy, while paper thickness and stiffness influence folding performance and structural integrity of finished boxes. Proper paper selection requires balancing printing requirements with functional performance characteristics and cost considerations to achieve optimal results for specific applications.

Professional offset printing operations typically achieve color accuracy within delta E values of 2.0 or less, representing color differences that are virtually imperceptible under normal viewing conditions. Extended color gamut systems can reproduce over 95% of Pantone colors, while spot color integration enables exact matching of specific brand colors. Advanced color management systems and real-time monitoring ensure consistent color reproduction throughout production runs and across different printing facilities.

Offset printing accommodates complex designs through precise registration systems that maintain alignment accuracy within 0.05 millimeters across multiple color stations and finishing processes. The technology supports integration with various post-printing operations such as die-cutting, embossing, foil stamping, and coating applications while maintaining print quality integrity. Sophisticated workflow planning ensures that all design elements and finishing requirements are coordinated to produce packaging that meets exacting quality standards and design specifications.