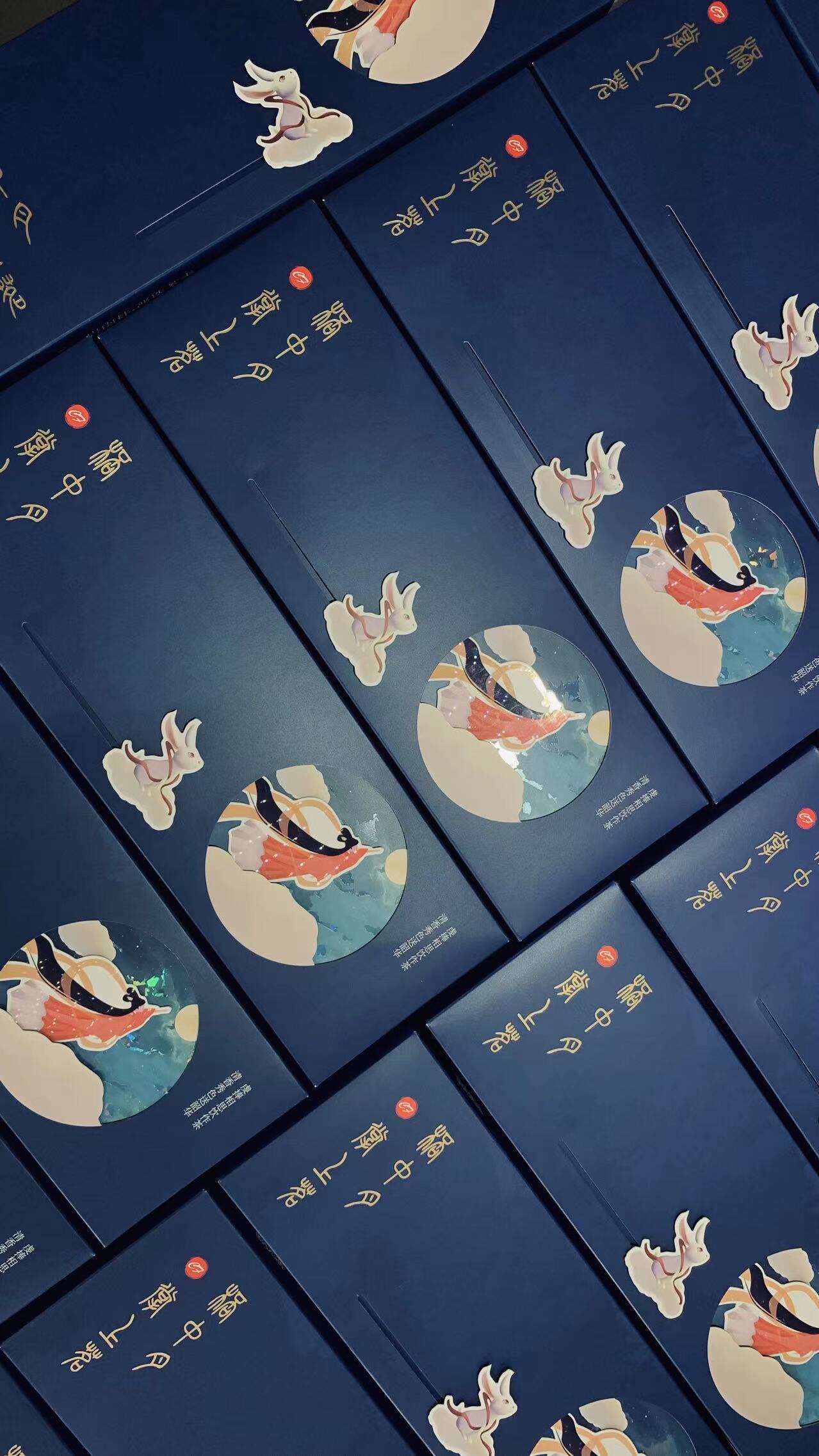

produktforpakkning udskrivning

Produktindpakningstrykning repræsenterer en sofistikeret produktionsproces, der omdanner råmaterialer til visuelt tiltalende og funktionelle emballageløsninger for mange forskellige industrier. Denne omfattende service dækker udarbejdelsen af skræddersyede kasser, etiketter, poser, beholdere og reklamematerialer, som fungerer som det første kontaktpunkt mellem mærker og forbrugere. Moderne trykning af produktindpakninger anvender avancerede digitale og offset-trykmetoder med højopløselige grafikker, levende farveskemaer og præcise efterbehandlingsmetoder for at skabe ekstraordinær visuel effekt. Processen starter med designkonceptudvikling, hvor kreative teams arbejder tæt sammen med kunder for at udvikle emballageidéer, der er i overensstemmelse med brandidentitet og markedspositionering. Professionelle ydelser inden for produktindpakningstrykning benytter topmoderne udstyr såsom flexografiske presseanlæg, digitale tryksystemer og specialiserede efterbehandlingsmaskiner for at sikre konsekvent kvalitet i store produktionsserier. Nøglefunktioner inden for teknologi inkluderer variabel datatrykning, som tillader personliggjorte emballageelementer, systemer til flerfarvet registrering, der garanterer nøjagtig farvematching, samt automatiserede kvalitetskontrolmekanismer, der overvåger alle produktionsfaser. Anvendelsesområderne for produktindpakningstrykning strækker sig over mange sektorer, herunder fødevarer og drikkevarer, lægemidler, kosmetik, elektronik og detailvarer. Hver branche stiller specifikke krav, såsom fødevaresikre blækker til spiselige produkter, fugtbestandige belægninger til udendørs anvendelser og manipulationssikre funktioner til sikkerhedsfølsomme varer. Nutidig produktindpakningstrykning integrerer også bæredygtige metoder ved at anvende miljøvenlige materialer og vandbaserede blækker for at mindske miljøpåvirkningen, samtidig med at den bevarer fremragende trykkvalitet. Avanceret egnethed til forskellige underlag gør det muligt at printe på mange materialer, herunder papkasse, plastfolier, metaloverflader og nedbrydelige alternativer, hvilket giver fleksibilitet til forskellige emballagebehov og sikrer optimal ydelse under forskellige opbevarings- og transportforhold.